MORE ON DESIGN CONCEPTS

All of my locos (with the exception of the High Level Models industrial loco kits) have been built with split axle chassis. The frames are joined using copper-clad spacers, and the wheels have to be ‘electrified’ in some way - more on that later.

I generally use three part split axles for the driven axle, and two part for the others. The more points of pick-

I generally use three part split axles for the driven axle, and two part for the others. The more points of pick-up the better - at least three wheels on each side, so an 0-4-2 will usually have ‘live’ trailing wheels. Having said that my 4-4-0 and 0-4-4 types have only two live axles.

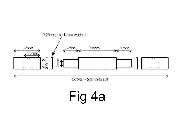

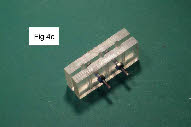

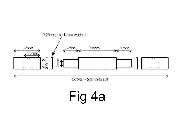

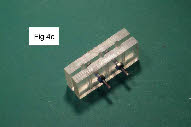

Split axles are easy enough to make if you have access to a lathe, but if not, they are more widely available commercially now than when I started. The dimensions I use are shown in figure 4a. Figure 4b shows some of the components, and 4c/4d show

the assembly jig in use. I use Araldite to glue the parts together, and have had only two or three failures over the years. It’s worth coating the perspex jig with Vaseline -

the assembly jig in use. I use Araldite to glue the parts together, and have had only two or three failures over the years. It’s worth coating the perspex jig with Vaseline - it stops the whole assembly getting more or less permanently glued together.

One minor difficulty of full compensation is the oft quoted problem of mounting the motor and gearbox. This is much less of a problem than it used to be, largely because of the introduction of high quality etchings for gearboxes, for example by London Road Models and High Level Models. When I started building locos, using open frame Anchoridge motors I built my own gearboxes - some successful, some less so.

Driving on a compensated axle, perhaps the centre axle with its sideplay, means that the motor and gearbox have to be able to move up and down, side to side, and to be able to twist and rotate in all directions, except for one -

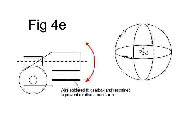

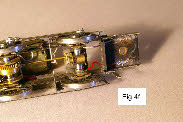

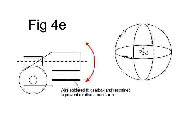

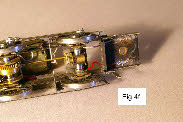

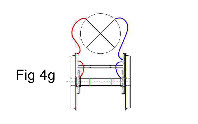

Driving on a compensated axle, perhaps the centre axle with its sideplay, means that the motor and gearbox have to be able to move up and down, side to side, and to be able to twist and rotate in all directions, except for one - the motor must be restrained from rotating around the axle it is driving. I’ve found that the simplest way to do this is to solder a piece of brass wire (0.5 or 0.75mm) to the gearbox, so that it protrudes under the motor. A wire loop soldered to a frame spacer can be used to restrain the motor - figures 4e and 4f show the basic idea.

The width of the gearbox obviously has to be less than the middle section of the split axle, but it doesn’t matter if the gearbox can move from side to side on the axle. The polarity of the gearbox may change, but as long as the motor frame is insulated, then whether or not the gearbox is live is of no consequence -

The width of the gearbox obviously has to be less than the middle section of the split axle, but it doesn’t matter if the gearbox can move from side to side on the axle. The polarity of the gearbox may change, but as long as the motor frame is insulated, then whether or not the gearbox is live is of no consequence - as long as it cannot short across the frames.

So in conclusion, what are the pros and cons of split axle construction? On the positive side, split axles are frictionless, reliable and maintenance free. On the negative side - mostly perception I think, about lubrication, insulating the body from the chassis, and doubts about the complexity of construction.

The loco picture gallery shows examples of chassis design.

All of my locos (with the exception of the High Level Models industrial loco kits) have been built with split axle chassis. The frames are joined using copper-

I generally use three part split axles for the driven axle, and two part for the others. The more points of pick-

I generally use three part split axles for the driven axle, and two part for the others. The more points of pick-Split axles are easy enough to make if you have access to a lathe, but if not, they are more widely available commercially now than when I started. The dimensions I use are shown in figure 4a. Figure 4b shows some of the components, and 4c/4d show

the assembly jig in use. I use Araldite to glue the parts together, and have had only two or three failures over the years. It’s worth coating the perspex jig with Vaseline -

the assembly jig in use. I use Araldite to glue the parts together, and have had only two or three failures over the years. It’s worth coating the perspex jig with Vaseline -One minor difficulty of full compensation is the oft quoted problem of mounting the motor and gearbox. This is much less of a problem than it used to be, largely because of the introduction of high quality etchings for gearboxes, for example by London Road Models and High Level Models. When I started building locos, using open frame Anchoridge motors I built my own gearboxes -

Driving on a compensated axle, perhaps the centre axle with its sideplay, means that the motor and gearbox have to be able to move up and down, side to side, and to be able to twist and rotate in all directions, except for one -

Driving on a compensated axle, perhaps the centre axle with its sideplay, means that the motor and gearbox have to be able to move up and down, side to side, and to be able to twist and rotate in all directions, except for one - The width of the gearbox obviously has to be less than the middle section of the split axle, but it doesn’t matter if the gearbox can move from side to side on the axle. The polarity of the gearbox may change, but as long as the motor frame is insulated, then whether or not the gearbox is live is of no consequence -

The width of the gearbox obviously has to be less than the middle section of the split axle, but it doesn’t matter if the gearbox can move from side to side on the axle. The polarity of the gearbox may change, but as long as the motor frame is insulated, then whether or not the gearbox is live is of no consequence -So in conclusion, what are the pros and cons of split axle construction? On the positive side, split axles are frictionless, reliable and maintenance free. On the negative side -

The loco picture gallery shows examples of chassis design.