Running signals for Brighton Road

Brighton Road needs quite a few running signals -

Brighton Road needs quite a few running signals - four on the lower level, and eight (or possibly sixteen) on the high level, although half of the high level ones are fixed distants.

On the low level there is a home and starter, at the extreme right hand end of the layout, controlling movements on and off the layout, and there are two calling-on arms, one to allow a shunt ahead to the starter, and the other to allow movement from the goods yard to the starter. All other movements are controlled by ground signals.

Brighton Road is set in quite a wide historical period, somewhere between 1900 and 1914, so it would just about have been possible to use slotted post signals, but in the end I decided to use conventional lower quadrant signals throughout, although the distant signals on the high level section are painted red as per early LBSCR practice.

All signals and turnouts on Brighton Road are operated electrically from control panels which are separate from the layout, so a reasonably efficient method of wiring up the actuators is called for. Also, because signals are fragile, I prefer a design where they are relatively easily removable, and the main requirement is that the actuating mechanism and the signal can be removed and adjusted separately, without having to disconnect everything.

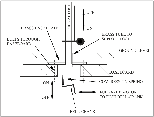

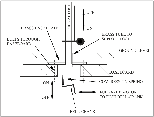

The basic signal design is shown in the drawing and photo. The signal is mounted on a base plate, with a couple of bolts to fix the base plate to the base-

The basic signal design is shown in the drawing and photo. The signal is mounted on a base plate, with a couple of bolts to fix the base plate to the base-board. The signal post is fixed into a short length of brass tube, soldered to the base plate. A small diameter length of tube passes through the base-plate for the operating wire. Soldered to the bottom of this wire (below the base-board) is a brass ‘button’ which retains a compression spring. Above the base-board the signal uses the rods and balance weight as per the prototype.

When the signal is detached from the base-board, it is ‘off’, and pushing upwards against the compression spring puts the signal ‘on’. The movement is supplied by a Fulgarex motor acting against a bell-crank as shown in the sketch. When installed on the layout, the bell-crank is not connected to the signal, but just pushes against the ‘button’. I have threaded a long 8BA bolt into the Fulgarex slider, and adjustment of the ‘on’ position at horizontal is achieved by screwing/unscrewing this bolt.

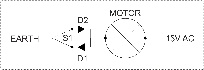

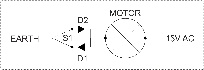

Brighton Road uses control panels separate from the layout baseboards, so to minimise the amount of wiring, I use the configuration shown. I have a 15V AC supply on the layout, and I use this for motors which need to be run in both directions (turnouts, signals, gates). Diodes are used to give half-

Brighton Road uses control panels separate from the layout baseboards, so to minimise the amount of wiring, I use the configuration shown. I have a 15V AC supply on the layout, and I use this for motors which need to be run in both directions (turnouts, signals, gates). Diodes are used to give half-wave rectification - positive when the switch S1 is thrown in one direction (via diode D1), and negative when thrown in the opposite direction (via diode D2). The motor will therefore run either forwards or backwards, depending on the position of switch S1. Only one wire is required between the control panel (switch S1) and the base board for each signal.

The final two photos show the signal as installed, above and below the baseboard. On the left, E1 ‘Strasbourg’ leaving the goods yard, and on the right, the Fulgarex motor, the bell-

The final two photos show the signal as installed, above and below the baseboard. On the left, E1 ‘Strasbourg’ leaving the goods yard, and on the right, the Fulgarex motor, the bell-crank and adjust able bolt as the push rod.

Brighton Road needs quite a few running signals -

Brighton Road needs quite a few running signals -On the low level there is a home and starter, at the extreme right hand end of the layout, controlling movements on and off the layout, and there are two calling-

Brighton Road is set in quite a wide historical period, somewhere between 1900 and 1914, so it would just about have been possible to use slotted post signals, but in the end I decided to use conventional lower quadrant signals throughout, although the distant signals on the high level section are painted red as per early LBSCR practice.

All signals and turnouts on Brighton Road are operated electrically from control panels which are separate from the layout, so a reasonably efficient method of wiring up the actuators is called for. Also, because signals are fragile, I prefer a design where they are relatively easily removable, and the main requirement is that the actuating mechanism and the signal can be removed and adjusted separately, without having to disconnect everything.

The basic signal design is shown in the drawing and photo. The signal is mounted on a base plate, with a couple of bolts to fix the base plate to the base-

The basic signal design is shown in the drawing and photo. The signal is mounted on a base plate, with a couple of bolts to fix the base plate to the base-When the signal is detached from the base-

Brighton Road uses control panels separate from the layout baseboards, so to minimise the amount of wiring, I use the configuration shown. I have a 15V AC supply on the layout, and I use this for motors which need to be run in both directions (turnouts, signals, gates). Diodes are used to give half-

Brighton Road uses control panels separate from the layout baseboards, so to minimise the amount of wiring, I use the configuration shown. I have a 15V AC supply on the layout, and I use this for motors which need to be run in both directions (turnouts, signals, gates). Diodes are used to give half-

The final two photos show the signal as installed, above and below the baseboard. On the left, E1 ‘Strasbourg’ leaving the goods yard, and on the right, the Fulgarex motor, the bell-

The final two photos show the signal as installed, above and below the baseboard. On the left, E1 ‘Strasbourg’ leaving the goods yard, and on the right, the Fulgarex motor, the bell-